In the contemporary industrial world, accuracy and effectiveness define the level of competition in manufacturing. From massive architectural domes and automobile structural parts to the sleek lines of furniture, these shapes usually depend on a crucial method: profile bending. As main machinery in this area, the profile bending machine, known for its great flexibility and exactness keeps pushing forward changes in techniques of working with metal.

I. Core Value and Industrial Basic Applications of Profile Bending Machine

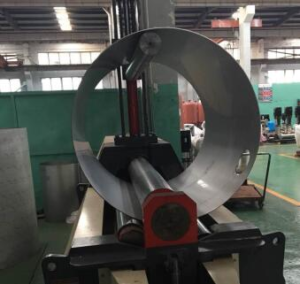

This type of equipment is used to bend metal profiles (such as pipes, angle steel, channel steel, etc.) into a set shape, applying force hydraulically or mechanically to achieve precise plastic deformation, significantly improving consistency and production efficiency.

1. Buildings and Heavy Structures

Profile bending machines are extremely common in architectural and structural applications. For example, large stadiums, airport terminals, and commercial complexes will have curved steel structure members, railings, or curtain wall support systems that require high precision in bending—a need fulfilled by Hydraulic profile bending machines because they can handle big sections of steel material providing for complex design curves while retaining structural strength. Machines of this type are indispensable tools where stable output force and excellent controllability add up to heavy metalworking.

2. Energy and power facilities

Energy equipment such as wind turbine towers and pipeline supports require extremely high bending quality. The 3-roll profile bending machine enables dieless continuous processing, suitable for medium and large-sized workpieces, effectively ensuring structural safety and production efficiency.

II. Cross-industry applications: from vehicle manufacturing to home art

Industry demands have made the use of profile bending machines much more than just heavy industry. For example, in transportation where chassis components, exhaust systems, and truck bumpers are manufactured, there is a requirement for very high bending accuracy as well as repeatability on metal profiles.

1. Vehicles and traffic equipment

such as automobile chassis and bumpers require high repeatability . The horizontal profile bending machine is easy to integrate into automated production lines, supporting efficient production of large batches and multiple product types.

2. Home and decoration design

Aluminum and stainless steel are the kinds of metals that are usually used in metal furniture, lighting, and other applications by bending them into some shapes. The Vertical CNC Profile Bending Machine supports flexibility in adjusting curvature through CNC program control hence very appropriate to customized high-variety production which greatly enhances design possibilities.

III. Technological Development and Future Directions

With the development of intelligent manufacturing in recent years, the technology of profile bending machines continues to advance. Most modern machines are able to accommodate CNC systems, sensor networks, and real-time correction ability thus machining accuracy and adaptability are improved.

1. Advanced Roll Bending and CNC Systems

The 3-roll profile bending machine utilizes multi-roll coordination and digital control to achieve die-free continuous bending, supporting multiple curvatures and small batch orders. Sensors and real-time deviation correction further enhance processing accuracy.

2. Composite Manufacturing and Flexible Production

The new equipment integrates multiple functions such as bending, punching, and cutting, reducing intermediate links, and particularly meeting the strict demands of the aerospace and new energy industries for high precision and manufacturing efficiency.

Conclusion

From big jobs to sleek looks, from making lots of parts to special touches, profile bending machines with their many types and strong output are key tools in today’s making world. Be it the steady force of hydraulic profile benders or the smart brains of CNC types, they keep moving the lines of metal shaping tech. As Industry 4.0 gets deeper, this gear will go on getting smarter and more joined up, helping makers everywhere do fancier and finer work.