Machine Introduction

The CNC four rollers have a pre bending function at the end of the sheet metal, which can load the sheet metal in one go without turning the head to complete the pre bending at the end of the sheet metal and the rolling and forming of the workpiece.

The working roller on the machine is the main driving roller, and the lifting of the lower roller and both sides of the roller are driven by hydraulic transmission. The lifting displacement is controlled by a computer, automatically leveled, and displayed on the screen, and the tilting and resetting of the flipping bearing body are driven by hydraulic transmission. The tail of the upper roller is equipped with a balance mechanism, which can facilitate the unloading of the rolled workpiece and cylinder. Equipped with a mobile independent operating table that can be moved and operated at any time, the machine is equipped with a safety interlock device.

The machine has a high technical level, full functionality, high accuracy, and convenient operation, making it an ideal CNC rolling equipment in contemporary times. It is the ideal preferred model for rolling circular, arc, conical, square, and multi segment arc shaped workpieces in industries such as energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, and metal structures.

Features

Dual-drive motor: with dual-drive design, equipped with mechanical brake and bi-directional balancing valve to realize double braking guarantee.

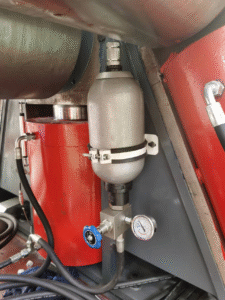

Accumulator: Used to protect the subsequent process of welding cylinder, correcting round to protect the roller shaft and hydraulic system.

Heavy-duty linear guide type structure: Adopting the most advanced design structure to ensure stability and accuracy.

High-quality roller material: The roller is made of high-quality forged material and undergoes strict heat treatment hardening process and precision polishing surface treatment.

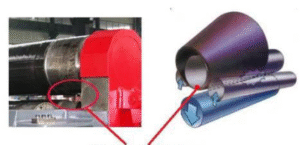

Clip angle pre-bending structure: CEIA® technology provides better pre-bending effect, which can control the straight edge of the plate head in the range of ≤1.5 times plate thickness.

Inverted Hydraulic Push Side Roller Cylinder (CIOC® System): Improves the stability of side roller sliding, reduces the height and center of gravity of the machine, and prolongs the service life of the cylinder.

Rolling system (CECB®): realizes smaller roll cone diameters and enhances rolling flexibility.

High-standard hydraulic system: including switching valve control system, proportional valve control system and electro-hydraulic servo system to ensure equipment stability and reliability.

Configuration of Siemens PLC system and high-end IPC industrial computer system: with rich functions and flexible expansion interface, providing efficient operation and control experience.

Technical Parameters

Standard configuration:

1. 42CrMo forged rollers

2. Welding bracket annealed and stress relieved

3. Tempering, quenching (roller surface hardening), roller surface fine polishing treatment

4. Frame-type heavy-duty welding chassis

5. Air cooling unit

Optional configuration:

1. Hydraulic automatic internal support inner material frame

2. Hydraulic side support frame

3. Non-powered/electrically powered feeding platform

4. Rolling cone device

5. Air conditioning and refrigeration system

Details

Dual drive motor (with mechanical brake and bidirectional balance valve to ensure dual braking).

Accumulator (for the straightening protection roller shaft and hydraulic system in the subsequent process of welding the cylinder).

Adopting the most advanced heavy-duty linear guide rail structure.

High quality roller shaft forging material, subjected to rigorous heat treatment hardening process, and surface polished.

Unique angle pre bending structure CEIA ®, to achieve better pre bending effect, the straight edge of the plate head can be controlled within ≤ 1.5 times the plate thickness.

Unique inverted hydraulic push side roller oil cylinder CIOC ® The system brings the following technological advantages:

By combining the oil cylinder and slider, an integrated side roller sliding oil cylinder is cast as a whole, greatly increasing the contact area between the slider and the slide rail and improving the stability of the side roller sliding.

The combination of the oil cylinder and slider shortens the length of the slide rail, lowers the height and center of gravity of the overall equipment, and reduces the cost of infrastructure construction.

The inverted installation structure protects the sealing ring, improves the service life of the oil cylinder, and reduces the maintenance rate of equipment failures.

Unique rolling system CECB ®, can achieve smaller cone diameter.

High standard independently developed hydraulic systems, including on/off valve control systems, proportional valve control systems, and electro-hydraulic servo systems.

1. It has functions such as misoperation warning, diagnosis, and maintenance reminders.

2. 30-120 steps of storage and operation, with large capacity data storage.

3. Rich configuration, with a 7-20 inch industrial touch screen for selection.

4. Rich expansion interfaces such as CAN/USB.

5. Bus design, flexible expansion through Ethercat communication.

6. Self developed software development platform with good program security.

7. Equipped with self-developed calculation functions such as automatic circle rolling, arc rolling, square rolling, and irregular rolling, convenient to use.

8. It can achieve remote diagnosis and repair overseas.

Samples

T1.2xH1200xΦ150xΦ400mm(SS304)

T3xH1250xΦ220xΦ1300mm(SS304)

T6xH3000xΦ450xΦ1500mm(SS304)

T8xW2500xΦ5800mm(stainless steel)

T12xW2000xΦ800mm(aluminum alloy 5052)

T35xW2000xΦ800mm(Q355)

Applications

- Concrete Mixer Trucks: 4 Rolls Plate Rolling Machine can be used to roll cylinders for concrete mixer trucks to ensure strong structure and good sealing.

- Bridge Guard Cylinders: Used for making bridge guard cylinders in rolls to ensure the strength and stability of the cylinders.

- LNG Gas Tanks: Suitable for manufacturing LNG gas tanks in rolls to ensure the safety and sealing of the tanks.

- Boilers: Can be used to manufacture boilers in coils to ensure strong structure and efficient operation of boilers.